|

Business and Technology : Biomass Effective Application Facility (High efficiency dioxin removal system) |

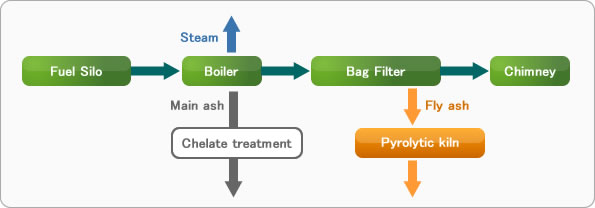

We completed a woodchip firing boiler for Hakozaki Utility Co.,Ltd at Fukuoka coastal Area. Hakozaki Utility Co.,Ltd. is a company to supply utilities such as electricity and steam with Hakozaki Food Industrial Complex and to have a plan to be able to continue daily 24- hour operation, yearly 320-day operation. To cope with the environment problems, Bag filter and Thermal resolution treatment furnace have been installed for exhaust gas system and ash system respectively to have a high removal efficiency against dioxin from exhaust gas and ash.

BOILER SPECIFICATION & OPERATION DATA CHART

| Boiler Type |

Bi-Drum, Natural circulation, Yoshimine H-1000 type |

| Combustion method |

Travelling stoker with Pneumatic spreader |

| Fuel |

Wood Chip 13.18 MJ/kg (L.H.V.) |

| Steam Evaporation |

29.01 t//h |

| Steam Pressure |

1.25 MPaG |

| Steam Temperature |

220 ±9 ゜C |

| ITEM |

UNIT |

DESIGN |

ACTUAL |

| Boiler Spec. |

Boiler efficiency |

% |

84 |

84 |

| Flue Gas |

Dust emission |

g/Nm³(O2=6%) |

0.05> |

Under 0.001 |

| SOx emission |

ppm(O2=6%) |

- |

51 |

| NOx emission |

ppm(O2=6%) |

200> |

190 |

| TEQ of Dioxin |

ng-TEQ/Nm³(O2 = 12%) |

0.1> |

0.00072 |

| Main Ash |

TEQ of Dioxin |

ng-TEQ/Nm³ |

0.3> |

0.01 |

| Fly Ash |

TEQ of Dioxin |

ng-TEQ/Nm³ |

0.3> |

0.01 |

As shown in the above figures, excellent achievement has been fulfilled that exhaust gas and ash dioxin content figures are about 1/140 and less than 1/30 of environmental limit respectively.

Outline Flow Chart