| Business and Technology : YOSHIMINE supplied ”YOSHIMINE WATER TUBE BOILER“ to Shimane nuclear power station of the Chugoku Electric Power Co., Inc. |

The unit 3 of power station (output 1,373MW) of Shimane nuclear power station is now under test operation for commercial operation.

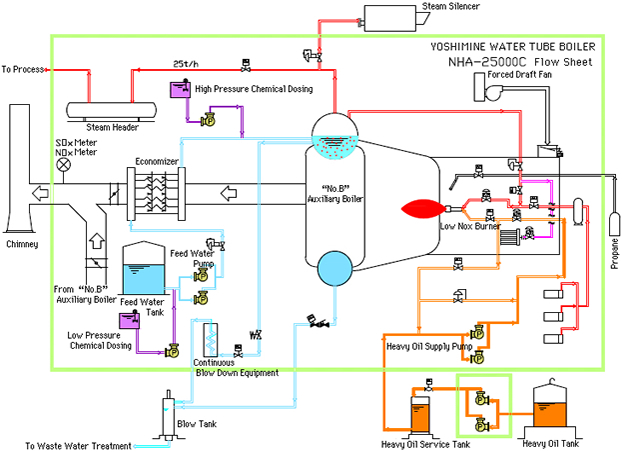

Yoshimine had contracted with Chiyoda Corporation on 2006 for 2sets of NHA type Yoshimine water tube boiler (Rated cap. 25TPH) as auxiliary boiler facility for unit 3 of power station. The boiler manufacture was started at Kyoto factory from 2009, then installation of boiler with facilities and piping works carried out on October 2009.

The boilers are under test running for supply of utility steam for examination and operation of plant now (May 2011), after finish of commissioning and performance test on April 2010.

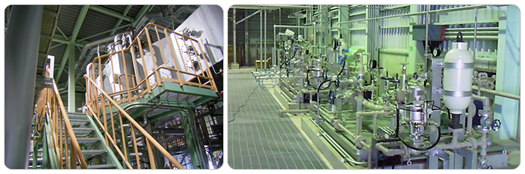

Front of No. A auxiliary boiler

Boiler specification

| Boiler type | Yoshimine water tube boiler NHA-25000C type |

|---|---|

| Quantity | 2 sets |

| Maximum operating pressure Normal operating pressure |

1.57 MPa 1.28 MPa |

| Steam temperature | 204 ℃(Saturate) |

| Feed water temperature | 15 ℃(at Feed water tank outlet) |

| Fuel to use Fuel consumption LHV of fuel |

A heavy oil 1,864 kg/h 41,860 kj/kg |

| Draft method | Forced draft |

| Maimum evaporation | Rating 25,000 kg/h |

| Boiler efficiency | Rating 85.0 %(HHV base) |

| Flue gas volume temperature |

27,900 m3N/h 167 ℃ |

| Heating surface total | 251.9 m2 |

Feature and Design of Auxiliary boiler

1) Design Process

Investigation by government for structure, strength and control method of Boilers

2) Manufacture Process

Investigation by organization for boiler structure and so on.

3) Installation Process

Inspection by national representative organization for boiler structure, strength and so on

Boiler controll method is employed remote-control by DCS system, and boiler can continuous operate stably at high and low load condition, and the system is adapted to be able to operate and monitor at local operation panel also.

DCS system consists of CRT monitoring at central control room and touch panel operation at boiler room as remote-control monitoring metod. Touch panel at boiler room can operate and monitor by functionable multiple windows such like Fig1 and Fig2.

Remote-control Monitoring

This auxiliary boiler has "High load operation" and "Low load operation" as operation mode, because this boiler is required absolute stable operation at low and high load as operational condition of auxiliary boiler.

This auxiliary boiler can start up automatically from stan-by condition at fill of water through burner ingnition and pressure rising until rating load operation by automatic sequence program.

The capacity of auxiliary boier is total 50 ton/h of MCR 25ton/h boiler 2sets. Steam consumption at normal operation is quite less, so the frequency of boiler start up and stop is expected to be increased. Therefore boiler function has On-Off operation sequence at low load condition, and minimum load is designed at under 4ton/hr for stable continuous running.

This auxiliary boiler has "Rapid start up mode" for steam demand from stand-by power station for emargency start up. The boiler can start up automatically through pressure rising until load operation within 50 minutes at this mode. And the automatic nitrogen injection is equiped for long-term storage when boiler stops.