| Our Products Top > H-Type: Large sized biomass firing boilers |

HIGH EFFICIENCY BIOMASS AND SEVERAL FUELS FIRING BOILER FOR POWER GENERATION

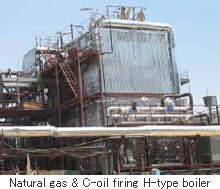

Since the establishment of Yoshimine, H-Type is utilized for many customers such like Plywood Company and Sugar Company, and recently it is utilized for power generation as a large sized high efficiency biomass fuel firing boiler. H-type also can use other solid fuel such as Coal, liquid fuel such as Heavy oil and Light oil, gas fuel such as LNG, LPG and City gas and etc. in addition to biomass fuels.

FEATURES OF PRODUCTS

- ・A NUMBER OF ACHIEVEMENTS

- The boiler gives the customer a technical security through a number of our achievement.

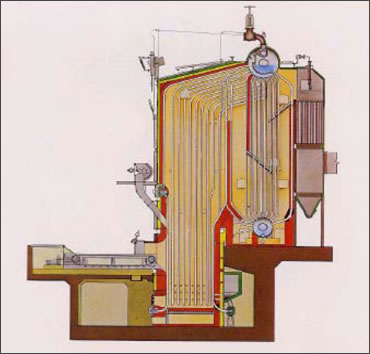

- ・THE MOST EFFICIENT WATER CIRCULATION SYSTEM

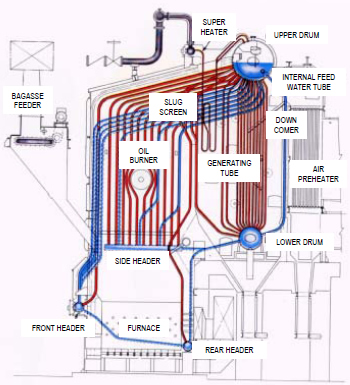

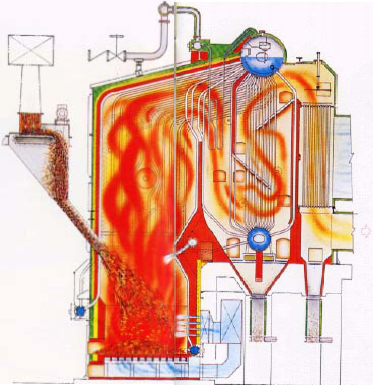

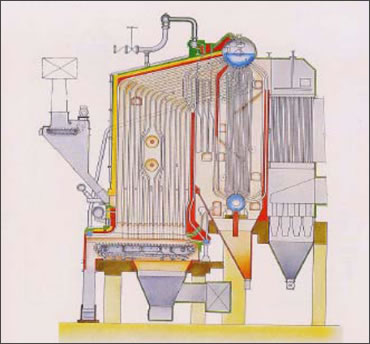

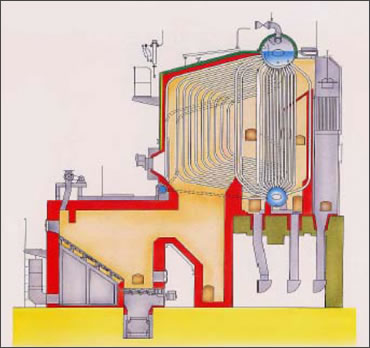

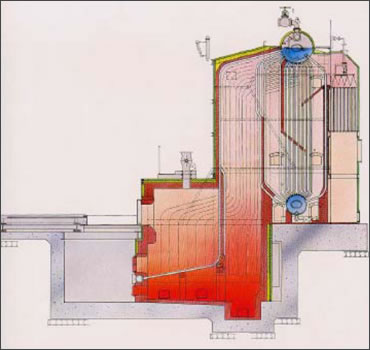

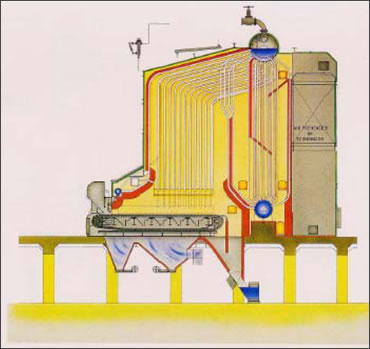

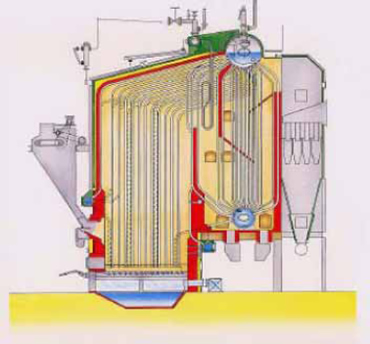

Yoshimine ’ s water circulation system ensures the greatest possible hat absorption. Water from the upper drum moves downward (blue lines) and collects in the lower drum and headers before moving up (red lines) and generating a mixture of water and steam. The high heat absorption that results improves the boiler ’ s efficiency for greater overall economy.

Yoshimine ’ s water circulation system ensures the greatest possible hat absorption. Water from the upper drum moves downward (blue lines) and collects in the lower drum and headers before moving up (red lines) and generating a mixture of water and steam. The high heat absorption that results improves the boiler ’ s efficiency for greater overall economy.

- ・THE MOST EFFICIENT GAS CIRCULATION

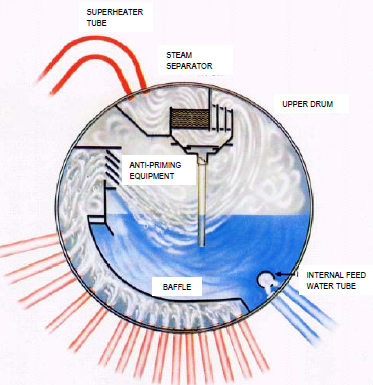

Yoshimine employs a unique steam separator in the upper drum to ensure that the steam is exceptionally dry and high in quality. The water and steam mixture is sent under a baffle which changes the mixture's direction before it reaches the upper drum. This removes water droplets from the steam. A steam separator then dries the steam, producing an extremely dry and high-quality steam which in turn improves the boiler's overall efficiency and economy.

Yoshimine employs a unique steam separator in the upper drum to ensure that the steam is exceptionally dry and high in quality. The water and steam mixture is sent under a baffle which changes the mixture's direction before it reaches the upper drum. This removes water droplets from the steam. A steam separator then dries the steam, producing an extremely dry and high-quality steam which in turn improves the boiler's overall efficiency and economy.

- ・THE DRIEST HIGHEST QUALITY STEAM

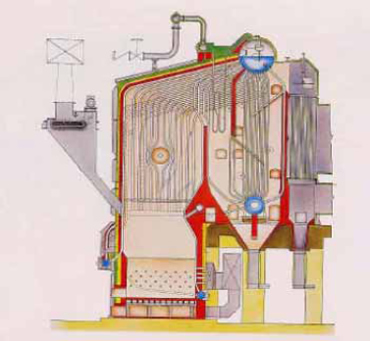

Complete combustion in the large combustion chamber produces heat which radiates and is absorbed by the water walls. Gas passing through the slug screen changes direction three times before passing through the preheater. Ash and cinder are separated from the gas and deposited in special "pockets" as the gas passes. This prevents ash and cinder from accumulating in the tubes and maintains the best possible thermal efficiency even when the boiler is used continuously for many hours.

Complete combustion in the large combustion chamber produces heat which radiates and is absorbed by the water walls. Gas passing through the slug screen changes direction three times before passing through the preheater. Ash and cinder are separated from the gas and deposited in special "pockets" as the gas passes. This prevents ash and cinder from accumulating in the tubes and maintains the best possible thermal efficiency even when the boiler is used continuously for many hours.

- ・EXCELLENT CORRESPONDENCE TO BOILER LOAD CHANGE

- Compared with other makers ’ boiler, this H-type boiler is more excellent in load correspondence.

- ・MOST POLLUTION CONTROL PROBLEMS HAVE BEEN SOLVED

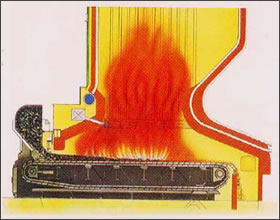

- Automatic fuel feeding and pneumatic control can facilitate combustion control, which can also stabilize a burning condition and pollution problems have been largely solved in regulation.

- ・CONTINUOUS OPERATION IS POSSIBLE

- Continuous operation is so possible that there is no need of ash discharging job, fire bed cleaning and rearrangement.

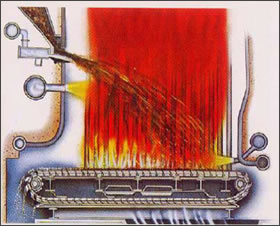

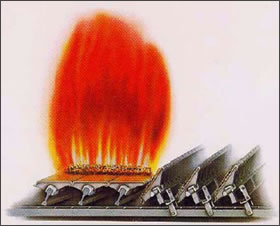

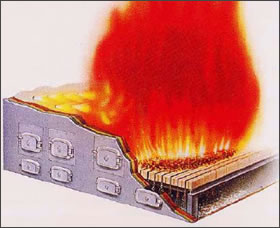

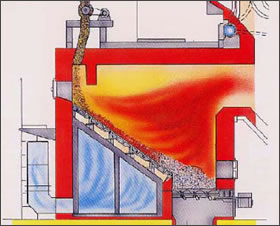

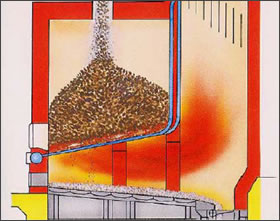

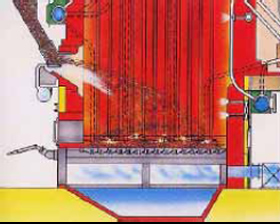

- ・STOKER SYSTEM

- These stoker system are capable of an easy future alternation of fuel from fuel A to fuel B and vice versa through partial improvement of fuel supply system.

VARIETY OF BOILER FUEL

Bagasse is the fibrous residue remaining after sugarcane or sorghum stalks are crushed to extract their juice.

Woodchips are a solid fuel made from woody biomass. According to the different chemical and mechanical properties of the masses, the wood logs are mostly peeled and the bark chips and the woodchips processed in different processes.

Rice husks are the hard protecting coverings of grains of rice.

Coal, a fossil fuel, is the largest source of energy for the generation of electricity worldwide.

Palm fiber and shell is the fibrous residue remaining after palm fruit bunches are crushed to extract their juice (oil).

At the request of customers, it is feasible to use a variety of Liquid fuel (heavy oil, light oil, waste oil etc.), Gaseous fuel (LNG, LPG, City gas, H2 Gas, Biogas, Waste gas from a Plant etc.) fuel with mono or dual-fuel burning system.

|

For fuels not listed above, we will chose the appropriate combustion system.

CONSTRUCTION

APPLIED FUEL :

BAGGASE, WOODCHIPS

RICE HUSK, COAL

APPLIED FUEL :

BAGGASE, WOODCHIPS

APPLIED FUEL :

WOODCHIPS

APPLIED FUEL :

RICEHUSK, WOODCHIPS

APPLIED FUEL :

WOODCHIPS

APPLIED FUEL :

COAL

APPLIED FUEL :

OIL PALM FIBER AND SHELL

APPLIED FUEL :

BAGGASE